The agricultural machinery industry is undergoing a rapid transformation, driven by advancements in automation, precision farming, and sustainable practices. With increased demands for efficiency, reliability, and fuel economy, the selection of critical components like gear reducers has become paramount. This article shares practical experience and insights into gear reducer selection for agricultural machinery, focusing on challenges, considerations, and emerging trends – particularly relevant in the context of the current push for Industry 4.0 and the Internet of Things (IoT) in agriculture.

Gear reducers are fundamental to the operation of numerous agricultural machines. They serve to:

From tractors and harvesters to sprayers and irrigation systems, gear reducers are integral components impacting productivity and operational costs. Poor selection can lead to premature failures, reduced efficiency, increased downtime, and ultimately, financial losses.

Choosing the right gear reducer is not a one-size-fits-all approach. Several factors must be carefully considered:

1. Load Requirements: Accurately determining the load (torque and force) the reducer will experience is the first step. This requires detailed analysis of the machine's operating conditions, including peak loads, continuous loads, and shock loads. Consider factors such as soil conditions, implement weight, and operating speeds. Many agricultural equipment manufacturers provide detailed load specifications.

2. Operating Environment: Agricultural machinery operates in harsh environments, exposed to dust, moisture, dirt, and extreme temperatures. The gear reducer must be robust and designed to withstand these conditions. IP (Ingress Protection) ratings are crucial. Higher IP ratings (e.g., IP65, IP67) indicate greater protection against dust and water ingress.

3. Efficiency: Energy efficiency is increasingly important for reducing fuel consumption and minimizing environmental impact. Look for gear reducers with high efficiency ratings. Planetary gear reducers often offer superior efficiency compared to spur gear reducers.

4. Maintenance Requirements: Ease of maintenance is essential for minimizing downtime. Consider factors such as lubrication requirements, accessibility for inspection and repair, and the availability of spare parts. Sealed gear reducers generally require less frequent maintenance.

5. Size and Weight: In agricultural applications, weight is a significant concern, especially for self-propelled machines. Choose a reducer that meets weight limitations without compromising performance or durability.

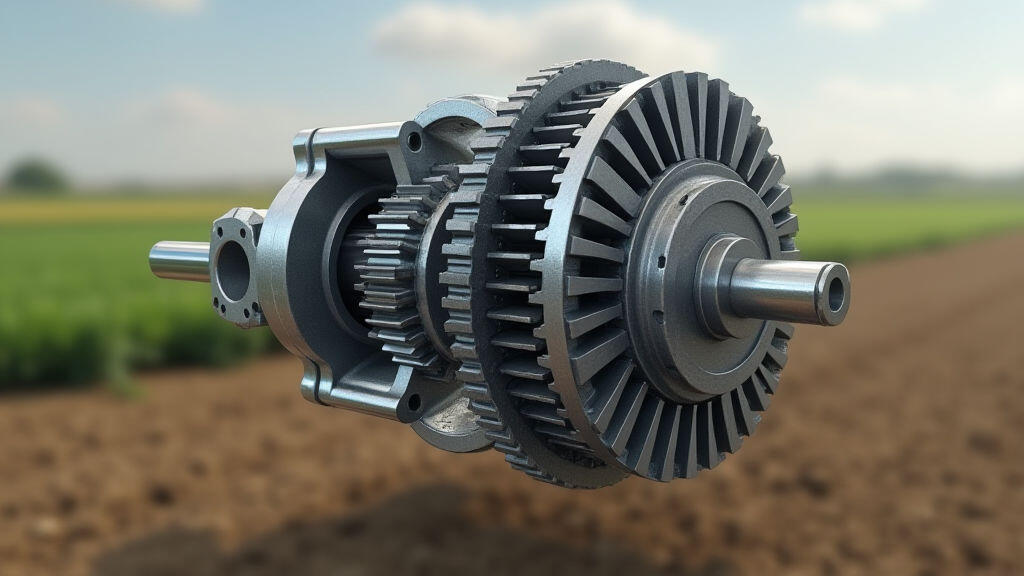

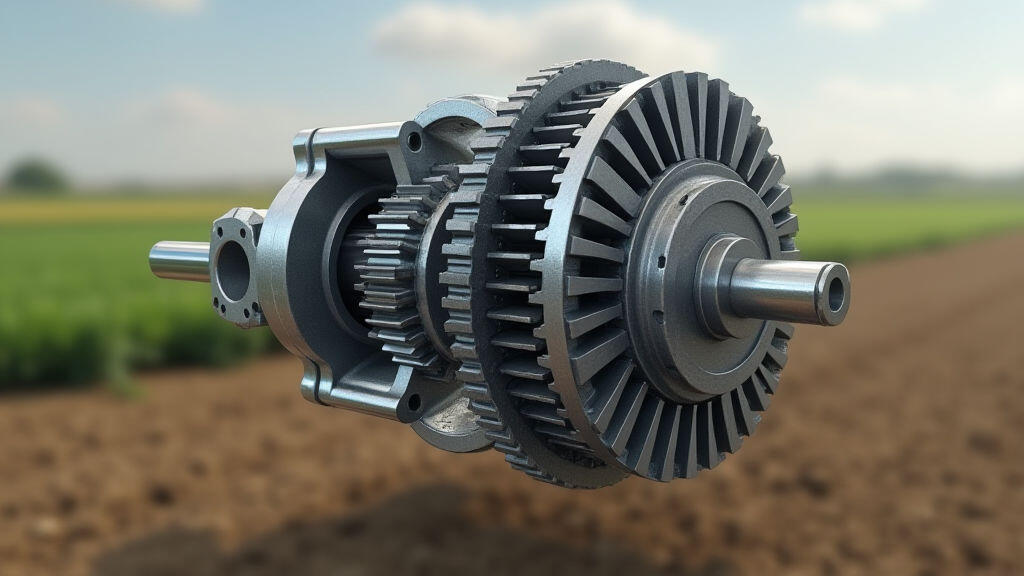

6. Transmission Type: Different transmission types each have their own advantages. Common types include: * Spur Gear Reducers: Simple and cost-effective for lower torque applications. * Helical Gear Reducers: Quieter and smoother operation than spur gear reducers, better for higher torque. * Planetary Gear Reducers: High power density, excellent efficiency, compact size, and smoother operation, making them increasingly popular.

The agricultural sector is embracing Industry 4.0, which involves leveraging data and technology to optimize operations. This has led to the integration of IoT sensors into agricultural machinery, including gear reducers.

Predictive Maintenance: IoT sensors can monitor vibration, temperature, oil pressure, and other parameters of the gear reducer in real-time. This data can be analyzed to detect anomalies and predict potential failures before they occur, enabling proactive maintenance and minimizing downtime. MES-Drive offers condition monitoring solutions leveraging IoT for predictive maintenance.

Performance Optimization: Real-time monitoring of gear reducer performance can help optimize operating parameters, such as engine speed and load distribution. This can improve fuel efficiency and extend the lifespan of the reducer.

Remote Diagnostics: IoT connectivity allows for remote diagnostics and troubleshooting, reducing the need for on-site visits and speeding up repairs. This is particularly valuable for large farms with extensive equipment fleets.

Our experience at MES-Drive (a company specializing in gear reducer solutions) and through collaborations with leading agricultural equipment manufacturers, has revealed several common challenges in gear reducer selection:

The future of gear reducers in agriculture is intertwined with the ongoing trends of automation, precision farming, and sustainability. Expect to see:

Selecting the right gear reducer is a critical decision for any agricultural machinery manufacturer or operator. By carefully considering load requirements, operating environment, efficiency, and maintenance requirements, and by leveraging emerging technologies like IoT and predictive maintenance, you can ensure optimal performance, reliability, and longevity of your equipment. The integration of smart technologies in gear reducer management, exemplified by solutions offered by MES-Drive, is poised to revolutionize agricultural efficiency, align with Industry 4.0 principles, and contribute to a more sustainable future for farming. The proactive monitoring and optimization enabled by these technologies will be key to maximizing the return on investment in increasingly sophisticated agricultural machinery.

Leave A Reply

Your email address will not be published. Required fiels are marked